There has never been a better time to work with the University of Edinburgh, particularly in the development and application of existing and novel advanced materials.

As well as enabling access to significant funding from the UK Government to support innovative collaborations, companies can directly commission research, accessing the University's facilities and expertise.

Edinburgh Innovations, the University's commercialisation service, partners with businesses to access the most relevant experts and facilities, identifying the most appropriate funding streams for each organisation and enabling each company to take advantage of our world-class research and knowledge base.

The content of this page is available to download as a PDF.

Our world-leading researchers are advancing the applications of materials, fluids and new processes, for our industrial clients. We provide a range of research expertise to support your business including:

For more information contact our team at materials@ei.ed.ac.uk

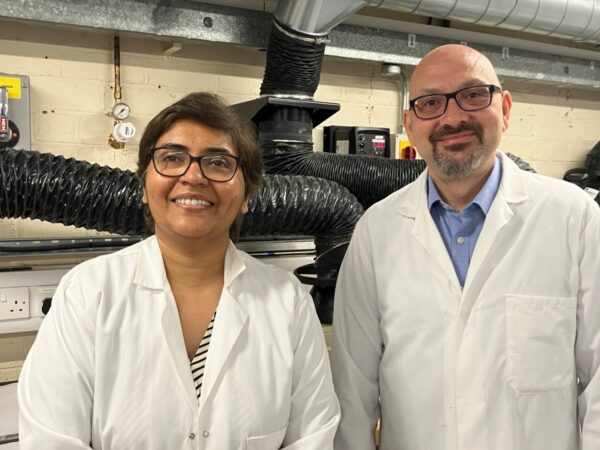

Our multidisciplinary team of physicists, biologists, chemists and engineers work seamlessly with industry partners to deliver rapid and meaningful results for commercial benefit.

Using a suite of bespoke techniques and equipment, we work on the full spectrum of fundamental and applied research projects, studying products, materials and their formulation that have complex flow properties, including gels, pastes, suspensions and composites.

The Edinburgh Complex Fluids Partnership supports product development in a variety of sectors including household products, cosmetics, food and drink, paints, agrochemicals, adhesives, lubricants, and pharmaceuticals.

The areas capabilities of our facilities that are available to companies include:

For more information contact our team at materials@ei.ed.ac.uk

The use of functional materials offers endless opportunities to innovate and improve your products. Work with us to take advantage of both the use and application of new and existing functional materials, for the creation of innovative new products, including:

For more information contact our team at materials@ei.ed.ac.uk

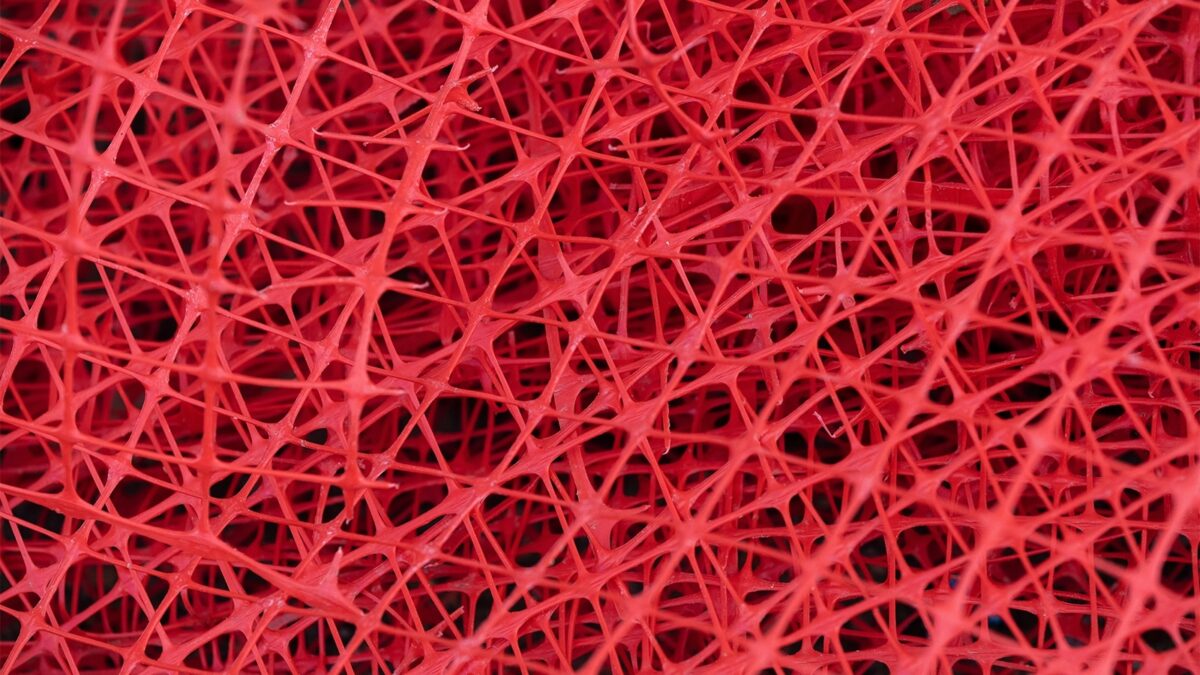

Research into materials relevant to the medical and healthcare sector is an area of specialism at the University of Edinburgh, from the modelling of materials and structures used in surgical implants to orthopaedic engineering and tribology.

Biomedical implants can improve the quality of life by enhancing the functionality of essential body systems, supporting damaged biological structures, or even replacing human organs. Research into the application of polymers and nanotechnology to modify the surface of implants for enhanced mechanical properties and biocompatibility is an area of research at the University available to be harnessed by companies in the healthcare sector.

For more information contact our team at materials@ei.ed.ac.uk

The University of Edinburgh is home to an extensive range of state-of-the-art facilities. Take advantage of these capabilities for physical testing, analysis, characterisation, structural and mechanical testing, non-destructive testing and processing of a wide range of materials and structures.

For more information please contact Michelle Holland.

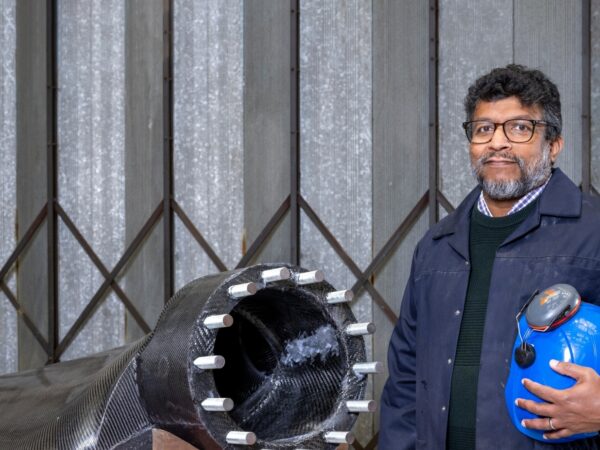

This innovative £1.8m research facility, the first of its kind in the world, is dedicated to the test and assessment of the mechanical performance of large structures under simulated fatigue loading. The facility enables faster fatigue or cyclic load testing of large structures and accelerated research into fundamental engineering options for new materials technology and quicker evaluation leading to more rapid certification and deployment to market.

The Structures Test Hall is our high-headroom lab for testing large and unusual structural assemblies. We offer a wide range of tests including strength, shear-friction, creep tests on concrete and steel specimens at high temperatures, or beam tests, inspection of failure surfaces and, structural testing under heat and fire. Analysis is made with high-speed data acquisition systems. We use digital image correlation for displacement measurement, structural health monitoring equipment, and non-destructive testing methods.

The Composite Processing Lab offers the novel processing of fibre-reinforced polymer composites, including thermoplastic and thermosetting polymers, using powder processing, liquid moulding, press moulding, in-situ polymerisation of thermoplastics and novel pre-pregging facilities.

The Advanced Adsorption Lab houses equipment such as zero-length column systems, dual-piston pressure swing adsorption system, membrane permeation cells and high-pressure static volumetric adsorption rig for adsorption characterisation of porous/membrane materials.

The Membrane Technology Lab offers a controlled environment room for high precision experiments, radiotracer facility, water purification system, cross-flow, stirred cell, submerged and electrodialysis membrane filtration systems and field-scale reverse osmosis and electrodialysis systems for larger-scale applications using our pilot systems.

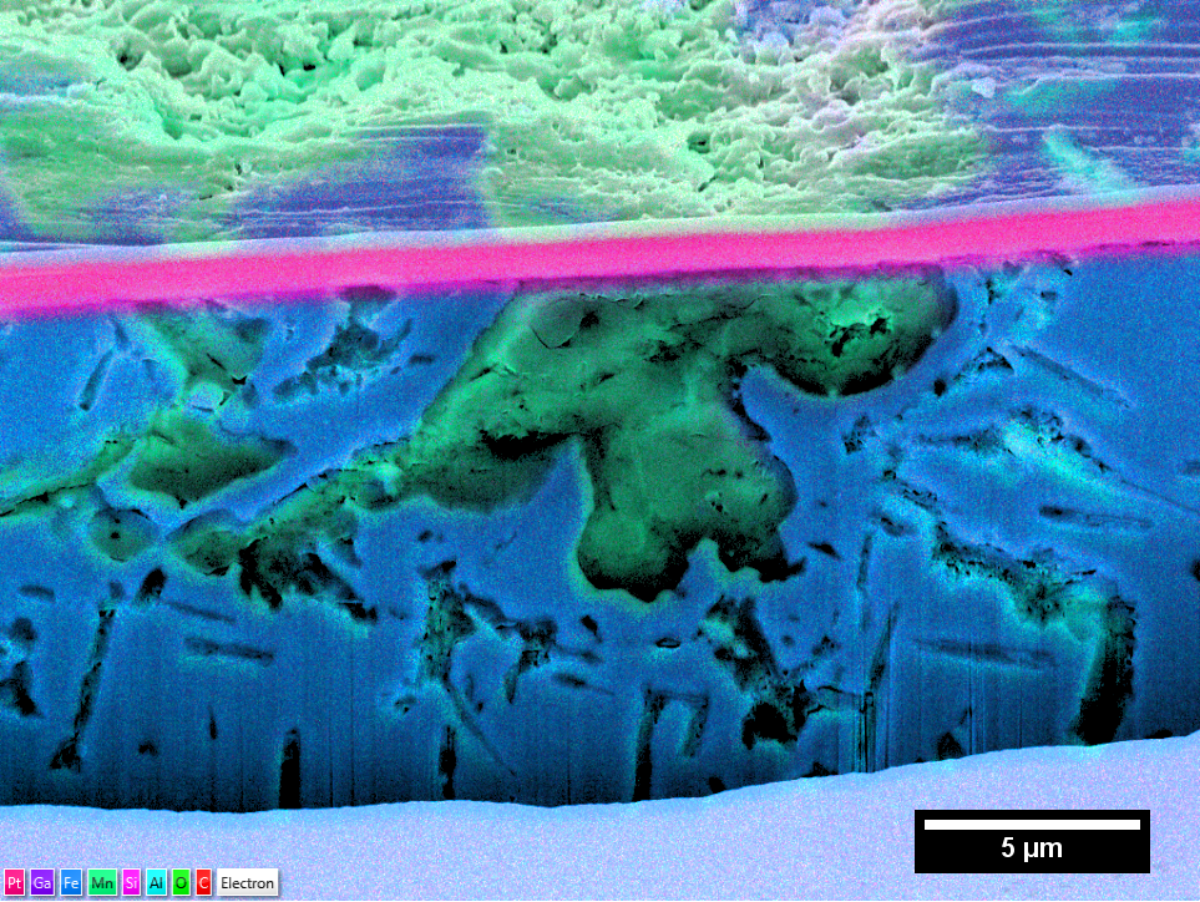

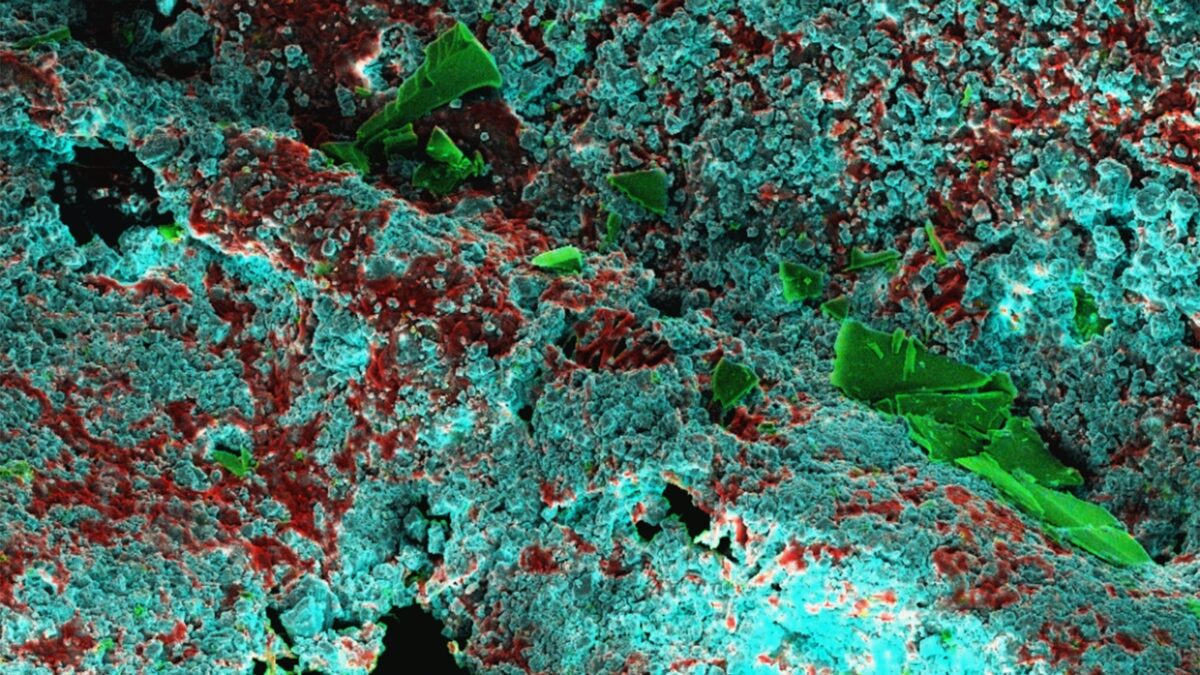

Cryogenic Focussed Ion Beam Scanning Electron Microscopy (CryoFIB-SEM)

This is one of only a few such instruments in the UK for imaging both soft and hard materials to nanometer resolution including obtaining elemental information. The focussed ion beam (FIB) enables micron-scale milling for slice and sectioning, patterning and TEM lift-out.

Rheo-imaging with a fast confocal microscope

Up to 100 fps at micron resolution) coupled to an Anton-Paar rheometer.

Atomic

Force Microscopy JPK NanoWizard 4XP

This advanced inverted Optical

Microscope combines with a new-generation AFM enables soft/biological

matter and material interfaces characterisation.

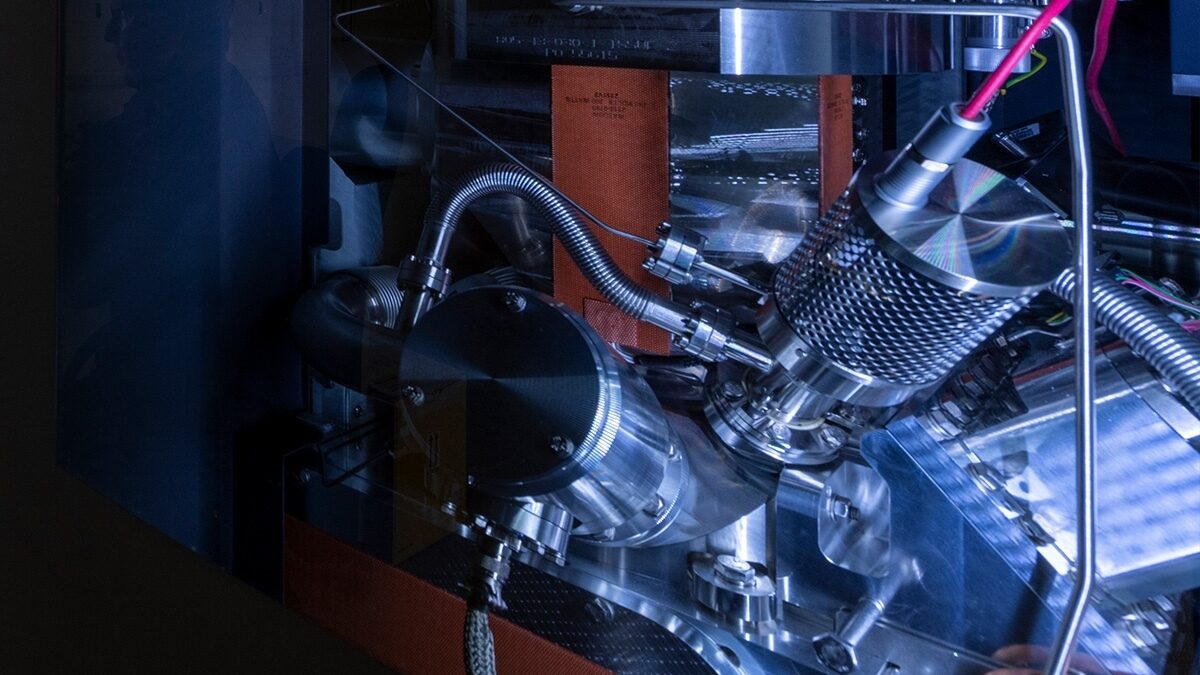

The Centre for Science at Extreme Conditions (CSEC) has a range of instruments that enable research experiments under extreme conditions not available elsewhere. These include:

- Shielded X-ray Laboratory containing a Rigaku Smartlab diffractometer with attachments for low and high T studies (12-620 K) simultaneous DCS/XRD studies, and a Photonic Crystal Orientation Lau diffractometer.

- Gas-loading Laboratory for loading under pressure into diamond anvil cells.

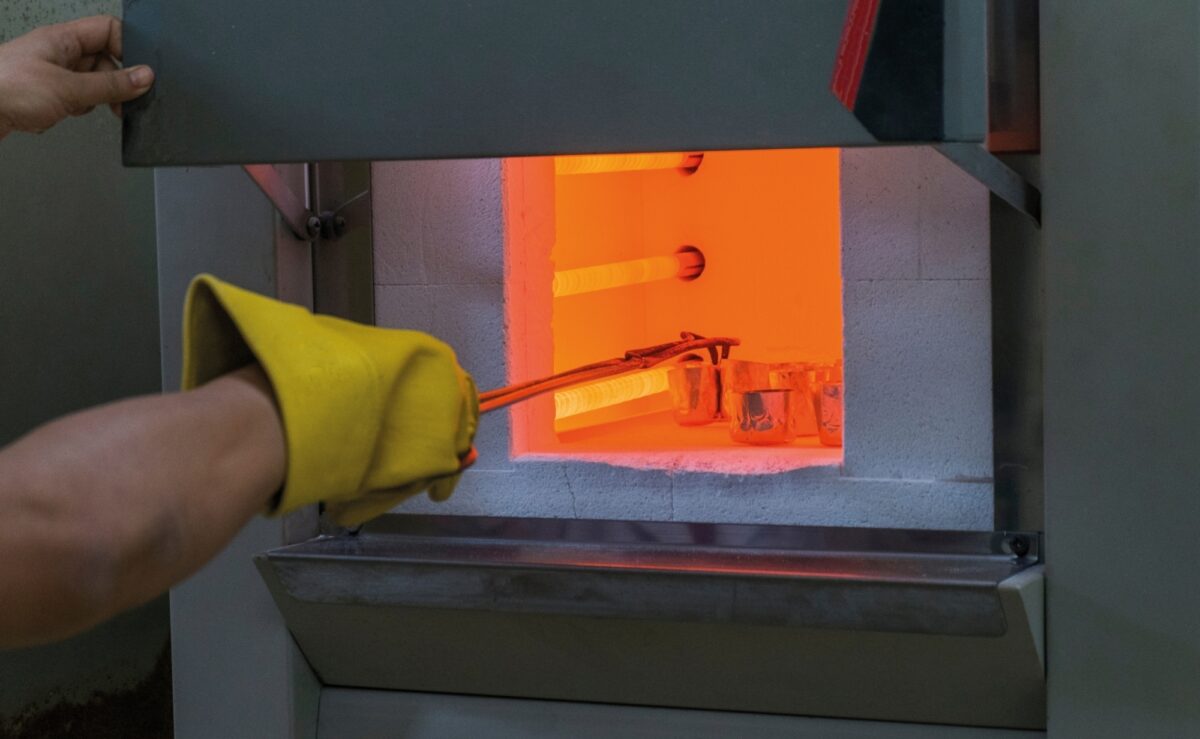

- Laser Heating Laboratory has a double-sided laser heating system for extreme pressure and temperatures studies with thermal conductivity measurements.

- Magnetism Laboratory houses all the equipment concerned with magnetic and transport property measurements: 9 Tesla Physical Properties Measurement Systems (QD PPMS) with electro-transport, vibrating sample magnetometry, heat capacity, 3He low-temperature options and other low-temperature transport measurement equipment. The laboratory also has 7 Tesla and 1 Tesla Magnetic Property Measurement Systems (QD MPMS) and a Closed Cycle Refrigerator system adapted for a variety of measurements.

Static and dynamic mechanical testing machines (50kN-300kN) for specialised testing of advanced composite materials with environmental chamber (-70°C to 300°C), non-contact video extensometer and Digital Image Correlation.

Nexsa G2 multi-technique surface analysis system:

Atomic Force Microscopy

Our Park NX20 AFM with specialist features: True Non-Contact modes, Pinpoint mode, Conductive AFM, Electrostatic Force Microscopy, Kelvin Probe Force Microscopy, Scanning Spreading Resistance Microscopy, Scanning Capacitance Microscopy, Piezoresponse Force Microscopy, Magnetic Force Microscopy, Temperature control and Adaptive scanning.

Scanning Electron Microscope

Electrical Characterisation

Capability to test a whole range of devices, such as memory chips, AI hardware, sensor modules and RF receivers.