This

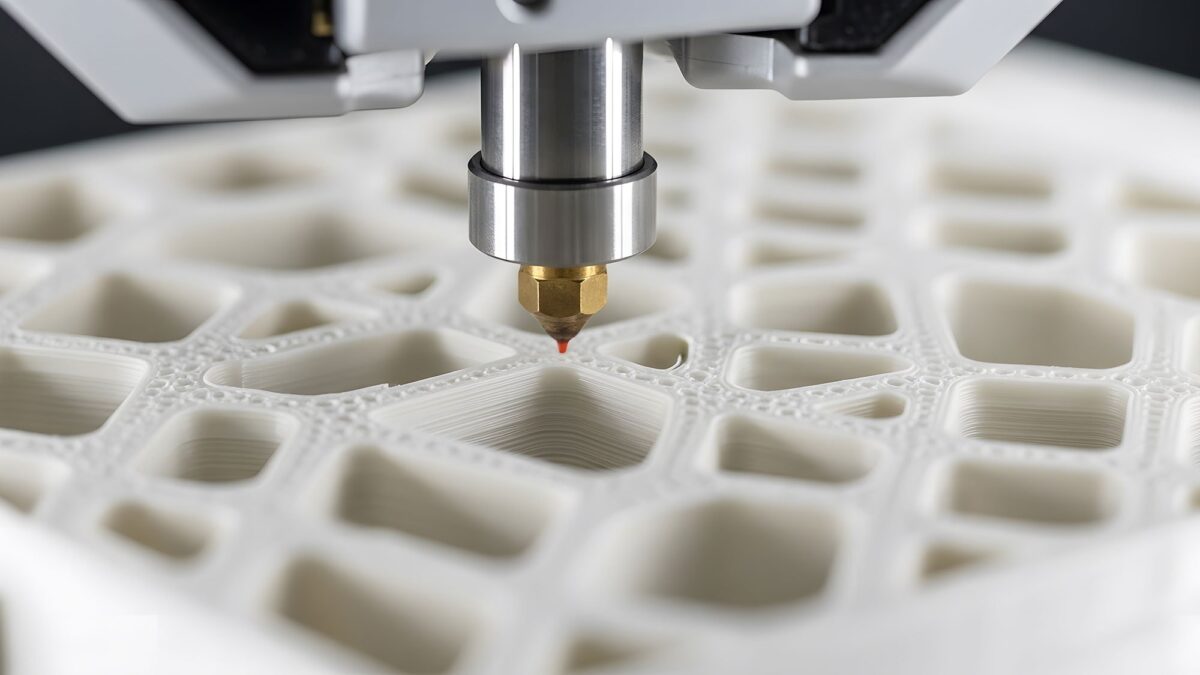

innovative solution efficiently tailors the cross-section of carbon fibre

composites during 3D printing, ensuring optimal structure and strength whether

crafting straight or curved rasters.

By combining superior fibre alignment and control, this technology promises to revolutionise composite manufacturing, offering unmatched precision and efficiency.

Application

Development Status

Undergoing validation

IP Status

Priority patent application

Commercial Offerings

Licensing or co-development/collaborative research

Opportunity

The Edinburgh Adaptive Nozzle introduces a major advancement in 3D printing with its ability to dynamically alter the cross-section of continuous carbon fibre (CCF) composites from rectangular to round during printing. This innovation addresses the limitations of traditional fixed-nozzle printers that struggle with different raster shapes, leading to disruptions or compromised fibre alignment. By seamlessly switching feedstock shapes in situ, this technology enhances structural integrity and eliminates the need for manual feedstock changes, offering superior efficiency and stronger, more reliable composite structures. This makes it a superior choice for industries seeking precise and versatile manufacturing solutions.

Technology

Our University of Edinburgh researchers have invented a new adaptive nozzle technology that surmounts the limitations inherent in conventional 3D printing approaches, particularly when dealing with AFP/ATP-graded CCF-PEEK materials. Traditional methods typically require tedious, ex-situ switching between rectangular tapes for straight rasters and circular filaments for curved rasters to optimally print parts with varied geometries. This not only interrupts the printing process, risking the continuity and alignment of carbon fibres, but complicates the production cycle and can affect the structural integrity and performance of the finished parts.

The innovative design of our adaptive nozzle allows for in-situ

transformation of feedstock from tape to filament and vice versa,

directly responding to the geometric demands of the print in real-time.

This seamless transition dramatically improves fibre alignment and

mitigates misalignment in both curved and straight rasters, enhancing

the mechanical properties such as tensile and compression strengths of

the 3D printed objects.

Moreover, the adaptive nozzle can switch modes without pausing the printing process, thus eliminating interruptions and promoting efficiency. This capability makes it especially suited for manufacturing complex parts that contain a mix of geometries, ultimately transforming complex composite manufacturing by enabling more intricate designs and superior structural qualities without the drawbacks of traditional fixed-feedstock systems.

Benefits

Quote: TEC1104679

Technology Transfer Executive

School of Engineering

School of Informatics

School of Geosciences

School of Mathematics