Gluten-related disorders affect a significant portion of the UK’s population. An estimated 1% of people face the potentially life-threatening immune reaction to gluten known as Coeliac disease, while another 20% have gluten-sensitive health conditions such as irritable bowel syndrome (IBS) and gluten ataxia that, while less severe, still impact on their daily lives. Avoiding gluten in foods like bread, pizza, and pasta requires a strict diet and drastically limits usual food choices.

Reimagining gluten-free bread

Gluten-free foods are becoming increasingly available, and the gluten-free food industry is currently valued at £835 million per year. Unfortunately for consumers, this market is still dominated by unappealing products that have an unpleasant texture and are typically two to three times more expensive than their standard diet counterparts. Sourcing the ingredients required to make gluten-free breads, such as rice flour, tapioca starch and certain additives, means they are often transported from across the globe, which both drives up the price point and increases the carbon footprint of each product.

One company seeking tastier and more sustainable alternatives for the gluten intolerant is biotechnology startup Prozymi Biolabs Ltd. Prozymi Biolabs has developed a pioneering method to craft bread and baked goods using a novel enzyme technology that neutralises only the toxic parts of gluten in wheat dough – a protein called gliadin that causes food sensitivities. This revolutionary method will preserve the taste, aroma, and texture people associate with popular bread products, while eliminating the health risks associated with gluten.

Fostering innovation

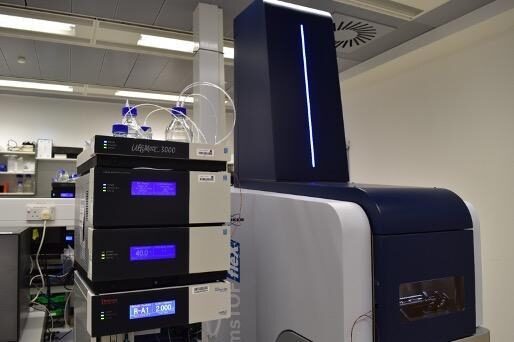

Prozymi Biolabs was founded by Dr Ioannis Stasinopoulos and Dr Andreas Andreou when they were PhD students at the University of Edinburgh. There they had access to entrepreneurial and business development expertise at Edinburgh Innovations, the University’s commercialisation service, and world-leading science facilities such as Edinburgh Genome Foundry (EGF), a research facility specialised in the modular assembly of DNA constructs using a highly automated robotic platform, and the Proteomics and Metabolomics Facility at the Roslin Institute, which provides advanced mass spectrometry instrumentations and expertise to help researchers advance their biomedical or clinical research programs.

The collaboration with the Head of EGF, Dr Rennos Fragkoudis resulted in the assembly of DNA constructs of Prozymi’s gluten-degrading enzymes, while the work with Proteomics and Metabolomics Facility Manager, Dr Dominic Kurian, led to the development of a robust and precise process for sequencing them.

Using molecular biology and analytical chemistry techniques such as gliadin zymography and mass spectrometry, the Prozymi Biolabs team was able to shortlist enzyme candidates that were produced from the previously isolated gluten-degrading strains. Next, they successfully identified exactly which part of the gliadin protein the enzymes would need to target to make wheat dough safe for consumption by those with Coeliac disease and other gluten-sensitive health conditions.

Access to high-throughput DNA cloning and mass spectrometry facilities was crucial for Prozymi Biolabs, as it enabled the budding startup to utilise the necessary equipment and expertise required to successfully complete its initial investigations. Without access to these facilities, the company would not have been able to progress its MVP development (gluten–degrading enzymes) and move on to proof-of-concept experiments.

Sustainable and gluten-safe

The technology developed by Prozymi Biolabs with the support and expertise of both facilities will eventually make possible the production of tasty and affordable wheat-based gluten-free bread, providing a viable and appealing choice for people with gluten intolerance. It will also mean that bread products for that market can still be produced using locally sourced wheat flour and cereals, thereby offering a range of products that are not only tastier and cheaper, but sustainable too.

The company envisions establishing new standards in the baking industry by introducing its pioneering Gluten-Safe technology. Prozymi Biolabs’ impressive achievements to date have received deserved recognition - the company was named the Wildcard winner at Scottish EDGE 19 in 2022, and more recently the Scottish Knowledge Exchange Awards 2024 awarded Prozymi Biolabs Innovation of the Year. The company’s proprietary enzymes have potential applications beyond bread: in beer production; the production of gluten-free animal feed that could potentially reduce methane gas emissions; and in the pharmaceutical industry, where it could be used to produce supplements for Coeliacs. In the meantime, Prozymi Biolabs are making great strides in the journey towards better-tasting gluten-safe foods.